Product Description

MEDICAL CLEANING SYSTEM (MCS)

The AM90100 Medical Cleaning System (MCS) is a powerful particulate control / source capture control tool in the Particle Trap® family of products designed to improve yields by reducing rework on devices and packaging. Perfect applications include:

- medical device manufacturing and packaging

- electronics

- food processing and packaging

- pharmaceuticals

No more blowing particulate around the manufacturing environment or cleanroom causing re-contamination. This problem occurs when using guns, nozzles, or other conventional blow-off devices that do not provide a means of capturing the dislodged particulates. The Medical Cleaning System is ideal for particulate control on medical devices & packaging.

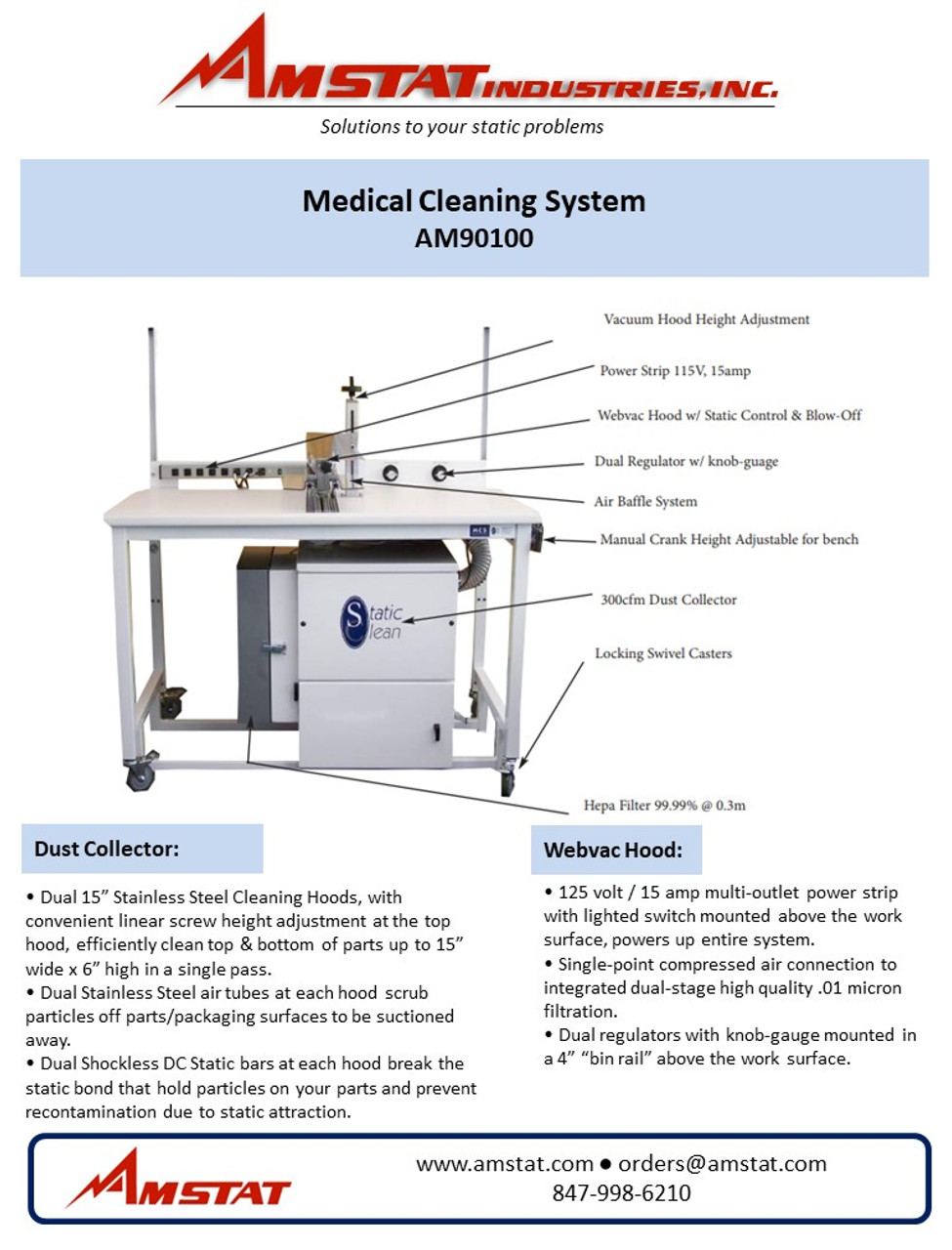

Parts are passed from one side of the Medical Cleaning System (the “pre-clean side”) over and through the cleaning zone in the work surface to the “clean side” of the system. The flush mounted bottom Vacuum Hood, which incorporates shockless DC static control bars and stainless steel compressed air tubes, removes dirt particles via static neutralizing. Both the blister / part and surface particulates and the electrostatic attraction that bonds and holds particulates to the blister part are removed through a filtered dust collector. This removal prevents recontamination due to static attraction. The upper hood of the Medical Cleaning System is adjustable to accommodate various sized parts or trays.

The powerful Dust Collector for the Medical Cleaning System draws a high volume of air into the cleaning hood, tapered along its length. This achieves an even, turbulent slot velocity to effectively remove surface contaminants such as angel hair, dust, human body hair, skin flakes and airborne particles. These contaminants cause rework and inefficiency resulting in poor profits and quality. The dust collector comes equipped with a magnehelic gauge, indicating the internal filter condition, and a HEPA Filter. The HEPA filter is 99.99% efficient by weight on the air exhaust for use in a cleanroom environment — feeding clean air back into the environment.

Questions? Contact Us