Product Description

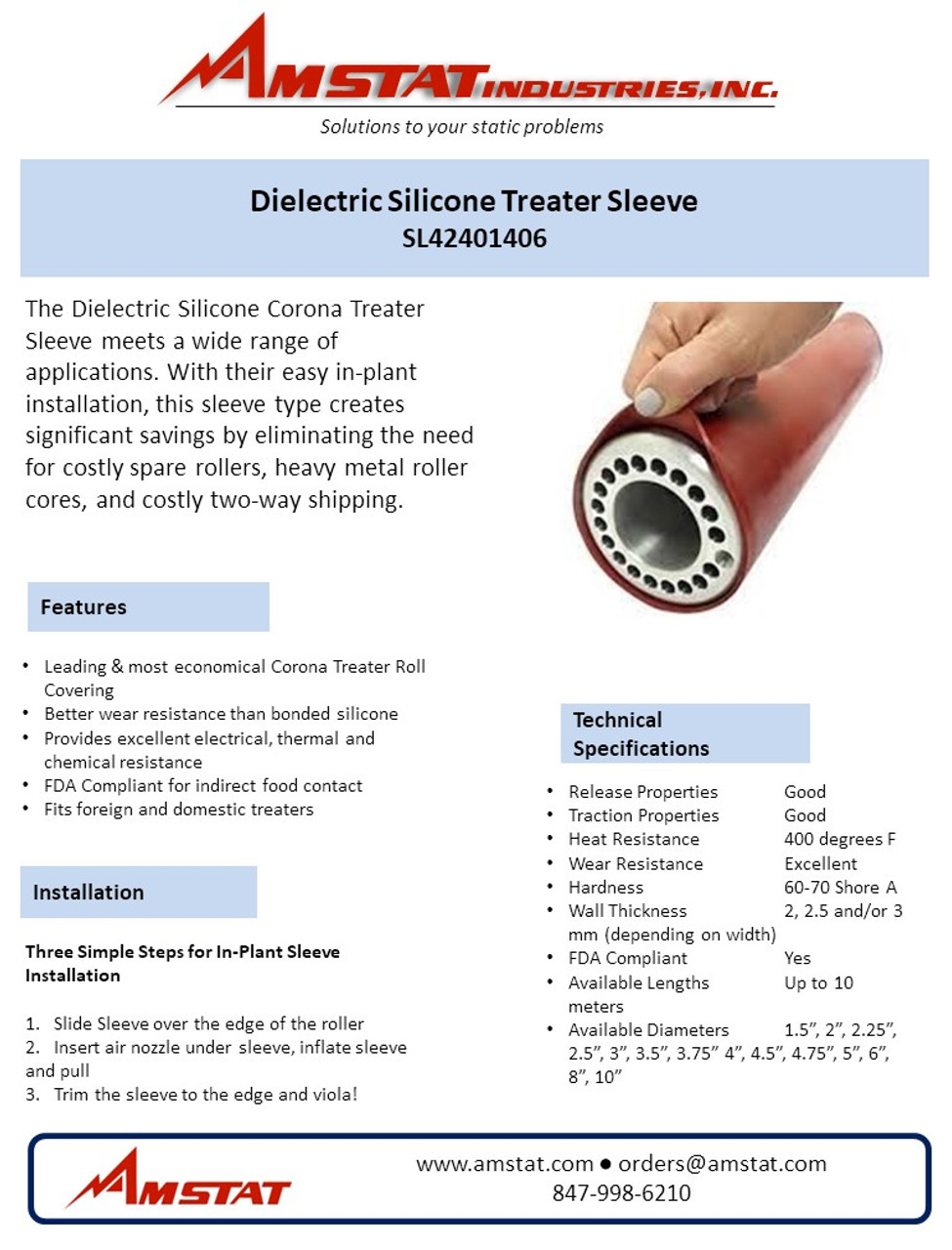

The Dielectric Silicone Treater Sleeve is an easy in-plant installation, and creates significant savings by eliminating the need for costly spare rollers, heavy metal roller cores, and costly two-way shipping. It's primary role is to act as a dielectric barrier, controlling the corona discharge during the treatment process and the overall corona treatment process plays a role in reducing static electricity on the material being treated. During corona treatment, the high-voltage electrical discharge ionizes the air around the material being treated, which can help neutralize static charges by redistributing electrons across the material’s surface. The Dielectric Silicone Treater Sleeve helps ensure that the corona discharge is uniformly applied across the material's surface, which contributes to effective treatment and the dissipation of static.

Ideal for covered roll treater applications

Features

- Manufactured to very tight tolerances

- Dielectric strengh of 350-400 in2/kw

- FDA compliant

- Fits foreign and domestic treaters

- Made to fit a wide range of roll diameters

- Available in sizes 1.5" to 10" diameters

- Custom sizes available upon request

- Available in custom lengths up to 10 meters long